Hardfacing

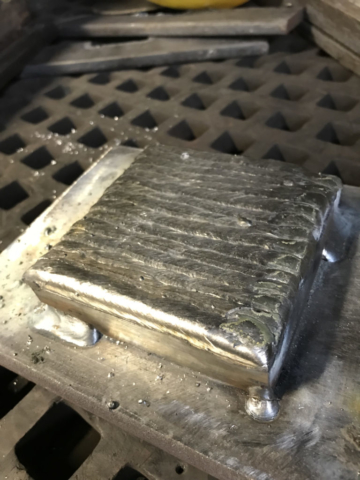

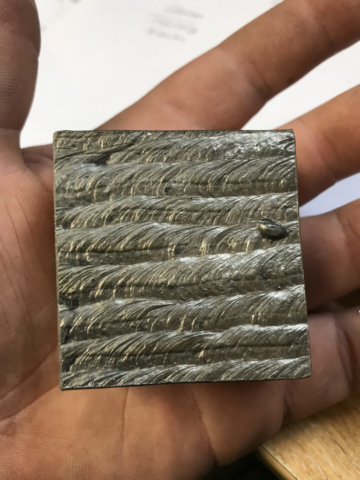

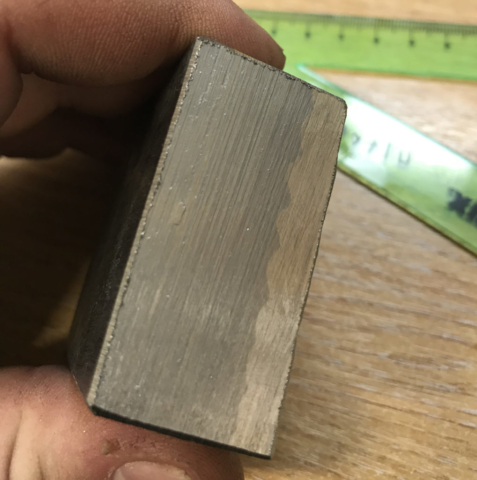

Here at M J B, we have been carrying out hardfacing operations on industrial process equipment for many years.

Primarily serving the aggregate, cement, waste recycling and construction industries, we are well versed in applying wear protection to equipment such as shredders, crushers, hammer mills, augers, grabs & buckets.

We have extensive experience with consumables from Welding Alloys and Castolin Eutectic, both world leaders in wear protection solutions.

Our experience with Welding Alloys products is unsurpassed, particularly using Robadur K600-G gas-shielded flux cored wire and Hardface HC-O and TIC-O, self-shielded flux cored wires.

Our services are available both in the workshop and on-site.

Our extensive knowledge of these products and application engineering allows us to achieve high deposition rates and the perfect balance of hardness, abrasion resistance and durability. Something we can back up with real-world data.

Hardfacing of your components can lead to an increase in performance, a longer lifetime and therefore a reduction in operational costs.

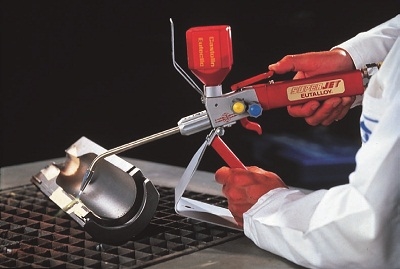

Thermal Spraying

M J B Engineering has invested heavily in thermal spraying equipment from Castolin Eutectic. This method is not a new concept but with more customers looking to repair parts or extend their lifespan, often turning to the latest developments can provide proven cost-effective solutions.

Flame spraying is one such method which can be used to deposit material with two methods – a cold spray process or a spray & fuse technique. Both can be used to deposit soft or hard metallic layers to the surface of the part to be coated.

Thermal spraying is ideal for providing wear protection with unique properties on shafts, augers, fan blades, tooling and many other types of equipment subject to impact, abrasion or corrosion.

Wear Plate

Along with hardfacing of parts and equipment we can also provide wear resistant linings and plate. We have experience working and fabricating with Hardox, Manganese Steel and Welding Alloy’s range of Multi-Metal Composite Wear Plates.

We can fabricate wear plate to create chutes, hoppers, pipework, ducting and everything in-between.

Cladding

We can carry out cladding operations with many different wires including Stainless, Nickel and Cobalt based, in all positions with all processes, manual and automated, both in the workshop and in-situ.